TS4000: The most efficient & effective fibre integration machine on the market

Published on Jul 5, 2021 12:22:58 PM

Topp & Screed is renowned for its global performance in the design, manufacture and maintenance of equipment for the production of concrete industrial floor slabs. Established in 2006, the company, situated in Luxembourg, has an extensive range of equipment and is renowned for its continuous innovation and cutting-edge technology.

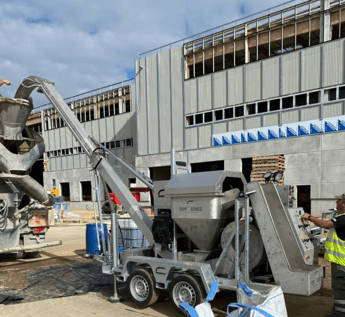

The TS4000 is the most efficient and effective fibre integration machine on the market. It homogenously mixes 2-3 tons of steel fibres per hour directly into concrete trucks. Suitable for all steel fibre types. Equipped with integral pumps (suction & discharge) for the controlled dosage of plasticiser into the concrete truck from a rigid pipe.

The use of a fibre integration machine ensures homogenous mixing of the fibres into the concrete. No balling of fibres will be seen. Controlled by experienced operators, defined quality controls are adhered to in terms of dosage to meet design criteria and uniformity of dispersion into the concrete. The machine’s components are made of stainless steel to ensure easy passage of fibres through the machine into the concrete mix.

Quality control is a critical success factor for SFRC and whilst there are alternative choices for integration of fibres; at the concrete plant or a belt conveyor, there are clear advantages to investing in a TS4000 Fibre Integration Machine to achieve:

- A homogeneous distribution of fibres in the concrete mix

- Controlling the fluidity of the concrete

- Precise addition of winter or summer plasticiser depending on climatic requirements

In addition to quality control, production time is supported by the speed of the operation with integration of up to 24 tons of fibres per day. Health & safety benefits include a hydraulic lifting mechanism, ergonomically positioned control panel and fibre loading bin.

Topp & Screed supports Twintec Group's core values commitment to sustainable solutions to reduce the environmental impact of our activities on the world we live in. The fibre integration machine is fitted with a diesel hatz engine demonstrating low emissions and long service life. Lower water/cement ratio concrete for SFRC, and plasticiser addition at the time of integrating the fibres, allows ethical choice of plasticiser.

WORKING WITH THE TS4000 FIBRE INTEGRATION MACHINE

The unique features of the fibre integration machine are the result of continuous improvement from site operation feedback and ongoing commitment to a robust research & development programme.

The fibre integration machine can be used by a single trained operator with easy to use controls on a single control panel, allowing the operator to view the entire operation from one position.

The concrete mixer truck reverses into position in front of the fibre integration machine. Steel fibres are placed manually in the stainless steel loading tank which is hydraulically tilted and discharged into the fibre separator. The loading capacity is 50kg (1 to 2 boxes). The loading bin is equipped with an automatic shock absorber to prevent shocks in the low position.

Once separated, the fibres are blown at high speed (adjustable) by a fan and venturi into the concrete trucks, through a stainless steel nozzle, positioned into the hopper.

The machine is equipped with a pump system (suction and discharge) for dosing the plasticiser which is injected directly into the concrete truck from a rigid pipe, allowing total quality control by the operator.

Suitable for every size/type of concrete truck due to the elevating cylinders that adjust the level of placement into the truck.

The machine is delivered as standard with an industrial frame, allowing easy movement on site by a telehandler. For transportation it can be loaded on a trailer or a modified road version is available to allow it to be towed behind a van (depending on local regulations).

RETURN ON INVESTMENT

The TS4000 Fibre Integration Machine, with the exception of the frame, is designed entirely in stainless steel that guarantees a longer working lifespan.

Research has clearly demonstrated that if a contractor directly purchases the concrete, steel fibres and plasticiser and integrates with the TS4000 Fibre Integration Machine on site, compared to buying SFRC from a concrete ready mix supplier, the return on investment will be realised after approximately 45,000m2 (excluding fuel, maintenance and transport).

TOPP & SCREED - GLOBAL PERFORMANCE

Part of the Twintec Group of companies, Topp & Screed is renowned for the design, manufacture and maintenance of equipment for the production of concrete industrial floor slabs. The in-house technical expertise and extensive knowledge offers customers a unique service worldwide.

In addition to the TS4000 Fibre Integration Machine, Topp & Screed offer Mini Electric Screeds, Superflat Screeds, Topping Spreaders, Triple Powerfloats – view the full product range

Topp & Screed offer new and refurbished machines with the flexibility to purchase, lease or rent. Contact us to discuss your specific requirements.

e.draganovic@toppandscreed.com

Topics: equipment

Comments

If you liked this article please share it or add a comment below