high performance, high tensile steel fibres Twintec AFT®+09/60HE

Published on 18 December 2023

Innovation is key to cost effective, performance solutions and the AFT®+09/60HE steel fibre from

Twintec is a prime example.

Performance

The performance advantage using the AFT®+09/60HE steel fibre allows for more cost-efficient designs whilst enhancing the performance and quality of SFRC. This is achieved by providing a steel fibre with a high tensile strength and good hook-end anchorage.

The performance advantage using the AFT®+09/60HE steel fibre allows for more cost-efficient designs whilst enhancing the performance and quality of SFRC. This is achieved by providing a steel fibre with a high tensile strength and good hook-end anchorage.

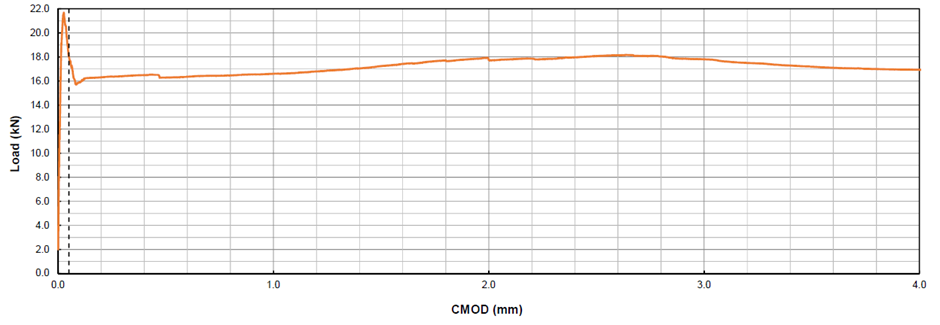

Testing

Beam testing incorporating the AFT®+09/60HE was carried out by Hanson QLD using a standard and readily available flooring mix, to demonstrate that the tested performance is relative to the in-use applications.

Beam testing incorporating the AFT®+09/60HE was carried out by Hanson QLD using a standard and readily available flooring mix, to demonstrate that the tested performance is relative to the in-use applications.

Engineers have stated they are impressed with the performance of the fibre and the test results are to European standards. All the beams were cast from one batch of concrete and utilised the results from ALL the beams cast (no picking and choosing the best results).

Dissolvable Bags

Twintec Australia introduced the first of its kind 10kg dissolvable bags for the AFT®+10/60HE steel fibres. The dissolvable bags allow concrete plants to load fibres easily and efficiently with no waste packaging materials to dispose of. This process also results in minimising balling due to the bags dispersing throughout the mix, dissolving, and then releasing the fibres in a more uniform fashion.

Case Study 1

The AFT®+09/60HE was used on a project in the Port of Brisbane, Rogers Transport at Hemmant for FKG Group and placed by DKA Contracting. Holcim are supplying the environmentally sustainable ECOpact concrete and a burnished finish is specified.

The AFT®+09/60HE was used on a project in the Port of Brisbane, Rogers Transport at Hemmant for FKG Group and placed by DKA Contracting. Holcim are supplying the environmentally sustainable ECOpact concrete and a burnished finish is specified.

A dosage of 35kg/m3 was required due to the poor ground conditions at the Port, resulting in the Engineer Northrop designing the slabs to sit on Controlled Modulus Columns (CMCs), which required additional SFRC performance and achieved by using the AFT®+09/60HE.

“The fibre is finishing really well, even with a dosage rate of 35kg/m3 ” - Dane Cox, Construction Manager, DKA Contracting.

The finish and the flatness levels achieved is exceptional. The AFT®+09/60HE is 60mm long and 0.9mm diameter and is an excellent example of high tensile strength of 2,100Mpa, good anchorage and a workable aspect ratio for ease of finishing – resulting in a ‘fibreless’ looking floor slab.

Case Study 2

The AFT®+09/60HE was used at a project in Wacol, Sealey Mattresses (MADAD) for McNab and placed by SETC South-East Total Concreting. Neilsens supplied the Burnished floor mix with the Twintec fibres.

The AFT®+09/60HE was used at a project in Wacol, Sealey Mattresses (MADAD) for McNab and placed by SETC South-East Total Concreting. Neilsens supplied the Burnished floor mix with the Twintec fibres.

A dosage of 25kg/m3 was used for the Internal Jointless Floor slab which resulted in a fantastic looking floor finish, with no fibres showing.

The AFT®+09/60HE was chosen due to its higher performance than the fibres specified, resulting in a more optimised slab design and a better finish being achieved.

“The fibre is a massive improvement over existing fibres for finishing and the result was a ‘fibreless floor’ - Dave Billings, Lead Finisher, SETC

Successful execution of SFRC floor slabs are not due to the fibres alone, the experience and performance of the project parties is a critical success factor.

Summary

The high performance AFT®+09/60HE is available in 1,200kg bulk bags or 10kg dissolvable bags and suitable for footings, hybrid slabs, jointless floors slabs, container hard stands, external HD pavements (with and without mesh), pile support slabs, CMC supported slabs and many precast applications.

If you want to consider AFT®+09/60HE for your next project in Australia, or any other Twintec AFT® product, please contact Andrew Hockey – 0474 560841 or a.hockey@twintecgroup.com.

For enquiries outside of Australia, please contact the international business team via r.waugh@twintecgroup.com

Topics: Concrete, #sustainable, steel fibres

Comments

If you liked this article please share it or add a comment below