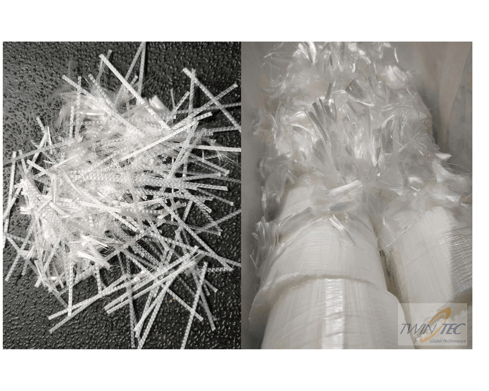

Blended High Strength Macro Synthetic Fibres and Monofilament Fibres

Published on 31 July 2023

Through industry research and applying 35+ years of knowledge, Twintec are excited to announce the introduction of the new AFT® TwinMesh macro and micro synthetic fibre solution for concrete reinforcement.

The AFT® TwinMesh is packaged in 4.6kg dissolvable bags, combining 4kg of Macro Synthetic fibres and 0.6kg of Micro Synthetic fibres. AFT® TwinMesh delivers benefits to the concrete in both the plastic and hardened state:

-

Outstanding post-crack performance.

-

Cost savings compared to supplying & placing wire mesh.

-

Minimises plastic shrinkage & settlement cracking in concrete.

-

Improves impact & abrasion resistance in concrete.

-

Easy to screed & finish.

-

Will not rust & safe under foot.

WE UNDERSTAND YOUR NEEDS ARE UNIQUE - SO ARE OUR SOLUTIONS

By offering 4.6kg fully dissolvable bags, not only does AFT® TwinMesh greatly reduce waste at the batch plant, but also minimises the likelihood of adding the wrong dosage rate. The dissolvable bags are environmentally friendly without sacrificing performance associated with using recycled plastic products.

The AFT® TwinMesh has been tested in Australia to the requirements of MRTS273, demonstrating great post crack performance and approved for use by TMR, Redland City Council and Gold Coast City Council to date. In many instances, AFT® TwinMesh can be used as an alternative to using SL62, SL72 and SL82 steel mesh.

By combining the benefits of Micro and Macro synthetic fibres, AFT® TwinMesh is suitable in a range of applications, including:

- Footpaths & cycleways

- Driveways

- Slab on ground

- Boat ramps

- Shotcrete

- Topping slabs

In November 2022, Twintec in collaboration with Austmix (concrete supplier in Brisbane) undertook a trial of the AFT® TwinMesh in a footpath for Redland City Council, with positive results. The mixing process was straightforward, with the bags dissolving and fibres dispersing almost immediately, with no negative effect on the concrete mix and provided a very uniform FRC mix.

The finish achieved on the surface using the AFT® TwinMesh was outstanding and testament to the testing conducted by Twintec of various diameter synthetic fibres to identify the optimum size for performance and workability, which can produce very different results.

Steve from Austmix commented that “It’s really easy working with Twintec, they provide a great service and have easy to use products”. The dissolvable bags on both the AFT® TwinMesh and AFT®+10/60HE steel fibres make batching simple.

Luke Hando of Hando Road & Civil stated that he was “Really happy with the TwinMesh fibre dispersal, the workability and ease of placing and finishing, as the fibres had no effect on the concrete”.

If you want to consider AFT® TwinMesh for your next project, or any other fibres in the Twintec AFT® product range, please contact the Australia Team:

Tel: +61 (0)474 560 841

Email: australia@twintecgroup.com

Topics: steel fibres

Comments

If you liked this article please share it or add a comment below