Reducing embodied carbon in concrete floor slabs

Published on 27 June 2023

i

Twintec integrates sustainability throughout its businesses - reducing environmental impact is a social responsibility to care for, and protect the environment for our generation and future generations to come.

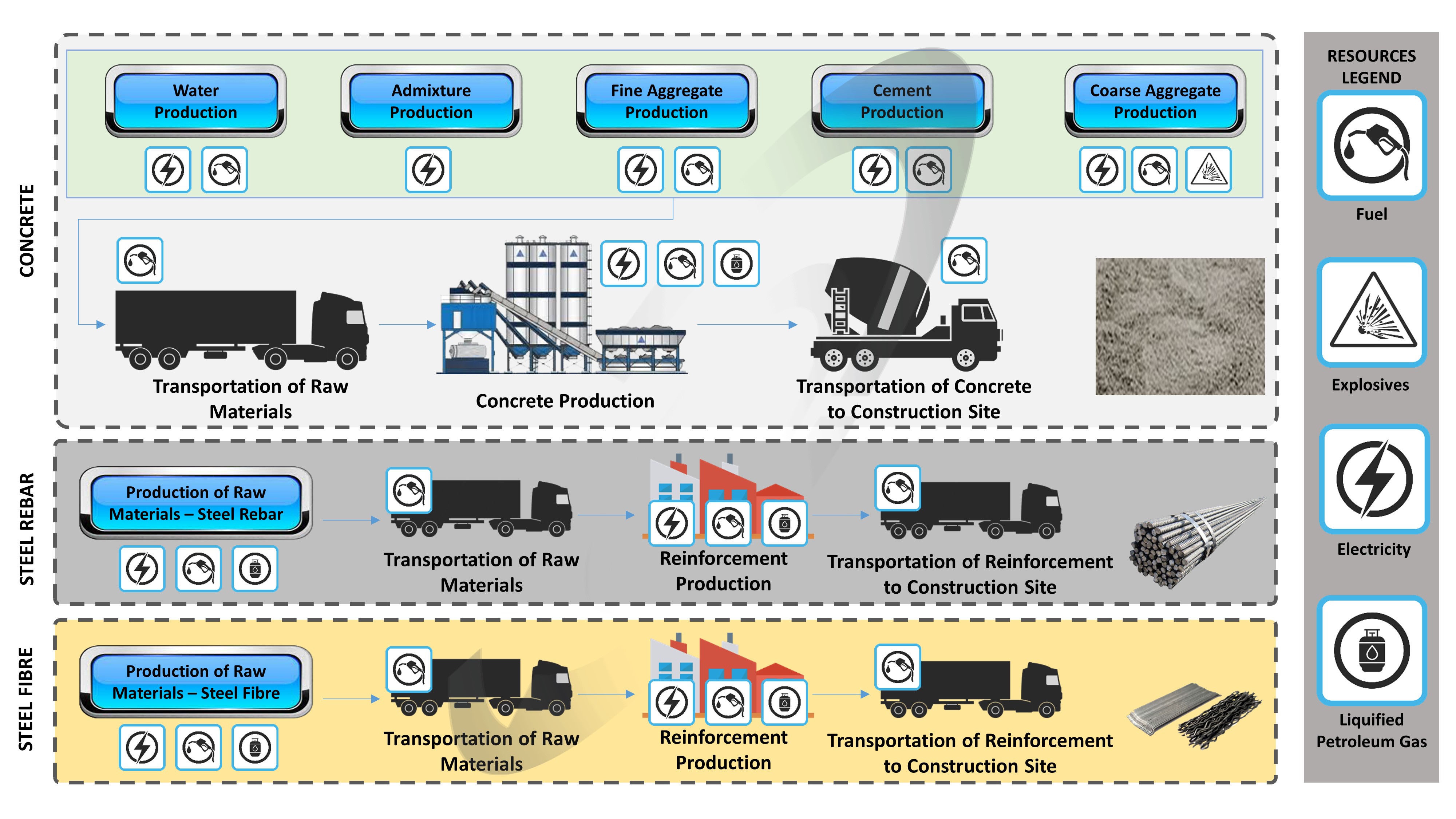

It is widely known that the embodied carbon or ECO2 emissions of concrete, steel and associated materials required for concrete floor slab construction has an impact on the environment - requiring energy to produce and distribute.

Cement is the source of approx 8% of the world's carbon dioxide (CO2) emissions and as one of the main components of concrete it measures roughly around 307.59Kg CO2e/m³ for a C28/35 mix design.

Steel rebar reinforcement emits approx 2.77 Kg CO2e/Kg for newly manufactured rebar.

Reduction in cement & steel bar usage in a concrete floor slab will significantly reduce CO2 emissions.

WHAT TWINTEC CAN OFFER

ECO Freeplan® floors are designed to optimise environmental sustainability and cast in large panels using steel fibre reinforced concrete (SFRC) - all the benefits of a Twintec Freeplan® floor plus a reduced environmental impact. It combines design solutions to optimise slab thickness & reinforcement, with specific materials and defined production processes for an overall reduction in embodied carbon (average 30%).

With the expertise of our Research and Development team, our slab design is optimized to provide a reliable solution to end-user with the highest consistency in design calculations and lessen the effect on the environment. Twintec ensures that specifications, loading requirements and all technical considerations are well measured and undergo value engineering assessment resulting in an optimized slab thickness design compared to the traditional slab resulting in a lesser concrete volume.

ECO FREEPLAN® ADVANTAGES

Optimised Design.png?width=300&height=176&name=Optimised%20Design%20(KSA).png)

Twintec ensures that specifications, loading requirements and all technical considerations are well measured and undergo value engineering assessment resulting in an optimized slab thickness design compared to the traditional slab resulting in a lesser concrete volume.

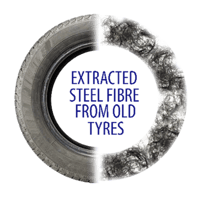

Eco-Friendly Materials

The steel reinforcement used in ECO Freeplan® is a combination of steel fibres extracted from end-of-life tyres steel and manufactured fibres that can significantly reduce the steel requirements and corresponding Carbon Dioxide (CO2) emission.

Shorter Casting Period

With the combined resources of state-of-the-art equipment and high skilled and experienced manpower along with site management professionals, the implications of emitting Carbon Dioxide (CO2) can dramatically decrease due to a significant reduction on casting timeline.

.png?width=353&height=114&name=Project%20Timeline%20(KSA).png)

Electric Powered Equipment

Optimum performance with substantial benefits and zero emissions, Topp and Screed concrete levelling machines are ideal for industrial concrete floors, freezers, parking areas, and other construction jobs. In addition to the environmental benefits, electric drives are low maintenance. This is a significant long-term benefit, reducing maintenance costs and time, and maximizing machine working time.

We’re in it to make a change.

Since the creation of Twintec in 1996, sustainability has been a foundation stone of our company and continues to be at the forefront of what we do.

We recognise that our business activities have an effect on the world we live in. The construction industry collectively is responsible for 40% of carbon emissions, we can’t change this alone, but we can contribute.

It is our duty and obligation to keep questioning ourselves. Sustainability and a commitment to reducing our environmental footprint is not a new or finished action, it’s ongoing every single day. At Twintec we seek through our research, development and eco-innovation initiatives, to have an impact in Design, Application, Equipment and Materials.

Julien Lazzari, CEO, Twintec Group Follow me

For enquiries outside of Saudi Arabia, please contact the international business team via r.waugh@twintecgroup.com

For further information contact us: info@twintecgroup.com

Topics: ECO

Comments

If you liked this article please share it or add a comment below