SFRC VS. SHRINKAGE-COMPENSATING CONCRETE

Published on 02 February 2021

Finished FREEPLAN® Floor with Mobile Racking, NAFCO Seafood in Jessup, MD, USA

We often speak about the differences between conventional unreinforced concrete (or concrete reinforced with rebar) and steel fiber-reinforcement, but perhaps not as frequently discussed is the difference between steel fiber-reinforced concrete and shrinkage-compensating concrete. Steel fibers provide many advantages over both traditional floors and shrinkage-compensation, which we will analyze in this article.

What is Shrinkage-Compensating Concrete?

Shrinkage-Compensation is a method used in concrete flooring where chemical additives or expansive cement is added to a concrete mix and the resulting expansion, if properly restrained, helps to offset strains caused by drying shrinkage. This is used to minimize the cracking caused by the initial drying shrinkage of the floor.

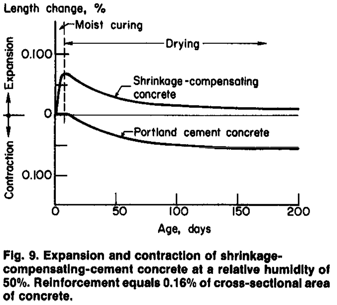

The graph below shows the expansion and contraction over time of shrinkage-compensated (SC) concrete vs. traditional (Portland cement) concrete. As you can see, SC concrete uses the initial expansion to offset the contraction (shrinking) you see in traditional floors.

Concrete itself has great compressive strength (resistance to breaking under compression) but lacks tensile strength (resistance to breaking under tension or pulling). SC concrete uses the compressive stresses caused by restraining the slab as it expands to compensate for tensile stresses caused by drying shrinkage. This restraint of the slab comes from several sources, but primarily from rebar or mesh reinforcement and friction between the slab and the subbase below it.

What is Steel Fiber Reinforced Concrete?

Steel fiber-reinforced concrete is concrete that utilizes steel fibers in the mix to provide the ductility and tensile strength that conventional concrete lacks. Contrary to concrete that uses rebar as reinforcement, which provides this strength in one or two directions, when properly mixed, steel fibers are homogenously spread throughout the floor and provide tensile strength in all directions.

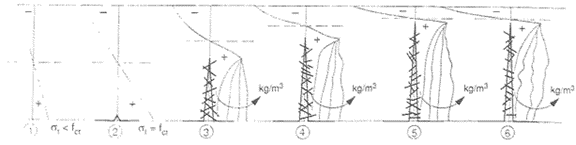

Apart from providing additional strength and ductility to the floor, steel fibers also help to minimize cracking by acting as bridges when cracks begin to form. Because the fibers are evenly spread throughout the floor, cracks that appear at any part of the floor, including the surface, will be held closed by these fibers. As seen in the image below, as cracks appear in the floor, the more the crack tries to expand, the more fibers will be there to bridge the gap and slow down growth.

Advantages & Disadvantages

While shrinkage-compensating concrete and steel fiber-reinforced concrete both allow for the elimination of saw-cut joints and add significant quality improvements to traditional floors, there are advantages and disadvantages to both methods.

Fibers

One of the more noticeable differences between SFRC and SC floors is the presence of steel fibers (typically only 1 or 2 visible fibers every 100 feet) at the surface of the floor. To some, the visibility of these fibers is not as aesthetically pleasing as a floor without them. However, these fibers at the surface are an indication that the ductility and crack-control offered by the steel fibers is present where you need it the most, the surface, which receives the most abuse from things like forklift traffic, heavy loading, etc.

Production Planning

The joint-openings between slabs are typically smaller for SC floors over SFRC floors, which can also mean that less joint filler is required. However, shrinkage compensation involves a period of expansion, which takes approximately 7 days. Because of this period, the pour schedule must be adjusted to avoid pouring slabs adjacent to one another while both are expanding. While this restraint would increase the desired compressive stresses in the slabs, the following shrinkage would result in an unacceptably wide joint-opening. SFRC doesn’t have this expansion period and with opening armored joints, it is viable to pour adjacent slabs back-to-back without this concern.

Concrete Mix Design

Another side-effect of this expansion period in SC concrete is the resulting pushing force exerted on perimeter walls and columns. This can pose a structural concern if not planned properly. It is also crucial that the chemical additives in the mix are handled properly in order to be effective. This means that extended experience with the product is required. Concrete mix designs for SC slabs require a higher water to cement (W/C) ratio, often around 0.55. This higher water content leads to greater shrinkage. A balance must be found between the increased water content and the expanding compound in the shrinkage-compensating mix design.

Structural Considerations

Also, for shrinkage-compensation, mesh reinforcement is necessary to post-tension the concrete during expansion (compressive stress). It is usually placed in the top third of slab depth for curling control; this means that reinforcement is not ideally placed for structural purposes (point loads require bottom reinforcement) and additional reinforcement needs to be added to the slab to increase the structural capacity of the slab. SFRC usually does not need additional traditional reinforcement to be added to the slab, as the addition of steel fibers provides the tensile capacities required to handle loads. This has an indirect advantage; slab pours can be finished in significantly less time than shrinkage compensated concrete as little or no rebar reinforcement needs to be installed in the field prior to pour. This also provides safety advantages as rebar can pose tripping/falling hazards on site during the pour.

For SC concrete, the goal is to build up as much compressive stress as possible to compensate for tensile stresses due to the slab drying. Only part of this can be achieved through the initial expansion process because, at an early age, the slab has very little stiffness, so the expansion’s resulting compressive stresses will be low. The reinforcement in the slab may reduce early age cracking but has limited effect on long-term crack formation due to drying shrinkage.

Impact Resistance

Additional advantages of SFRC over SC concrete include higher impact resistance and increased toughness of SFRC, such as that in the Twintec FREEPLAN® floors. The distribution of steel fibers so close to the top of the slab provides inherent strength at the top surface of the slab allowing it to withstand impact loads.

Crack Control

One other strong advantage that steel fiber-reinforcement has over shrinkage-compensated concrete is the crack control after the initial drying period of the slab. While shrinkage-compensation will prevent initial shrinkage cracks, should a crack appear later in the lifetime of the floor, there is nothing to prevent that crack from growing like there is in a steel fiber-reinforced slab.

Cost Analysis

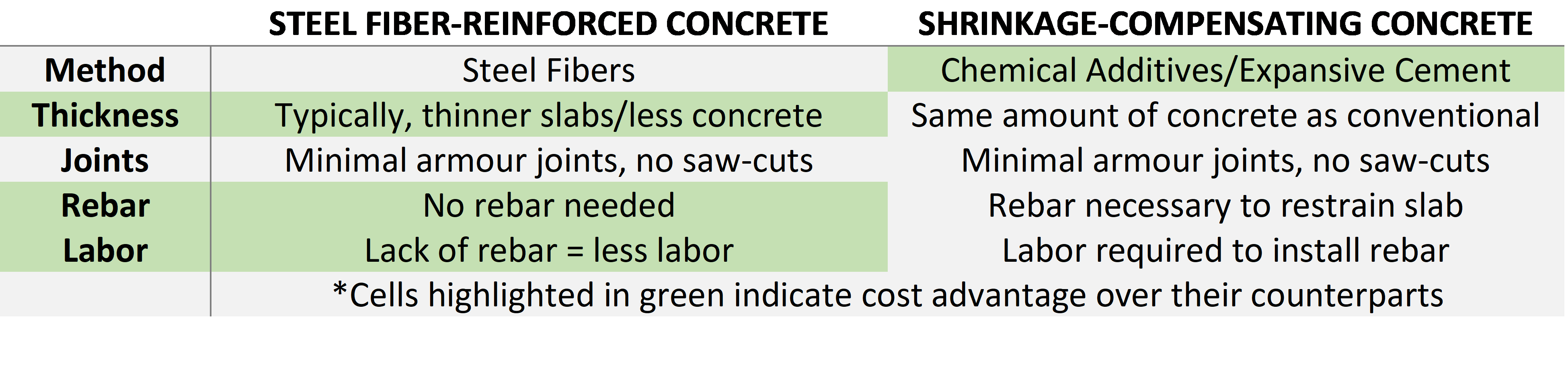

Because every region and material supplier’s costs may differ, and because every project may have different requirements, it is difficult to assign specific dollar amounts to these two flooring systems. However, we can draw direct comparisons to materials or labor that are or aren’t required for the two. See the table below for these comparisons:

Based on the differences in material and labor requirements shown above, the conclusion can be drawn that when comparing SFRC floors to SC floors, one can expect the cost of SFRC floors to be lower overall. This can, however, change depending on specific project requirements and specifications.

It should also be noted that it is possible to combine the technologies of steel fibers with the technology of shrinkage compensation. There are advantages to this technology, but it comes at a significant cost increase and for the purposes of this blog we chose to focus on the comparison of the two flooring systems individually.

Conclusions

In summary, long-term crack control, increased ductility, and enhanced load-bearing capacity are just a few of the ways that steel fiber-reinforced flooring is revolutionizing the flooring industry. While shrinkage-compensating floors provide a much needed improvement to traditional slabs, they fall short when compared to the many advantages of steel fibers.

What We Offer: Design-Build-Guarantee

At Twintec, we are happy to provide our clients with a total offer concept.

This means that we are fully involved with each project from the initial design phases with our in-house engineering team, through the building of the project with our experienced and talented workers and place & finishing partners, and finally in providing each client with our unique guarantee. Our goal is to always meet the unique needs of each client through a long-term partnership as their concrete floor slab experts during and after our slab system is installed.

Future Innovations in Floor Slab Design

There are a few certainties in life, and one of those certainties is that concrete cracks.

Thankfully, as new technologies are developed every day, we are learning to minimize these cracks much more effectively and are using these tools to better serve our customers.

One of the latest innovations designed by Twintec is a product called Twintec ULTIMATE® which uses steel fibers paired with mesh to achieve an end user's ultimate requirements for a totally seamless floor slab by eliminating opening joints entirely.

Contact Us

We pride ourselves in our wealth of engineering and construction knowledge and hope to provide our clients with the confidence that they are getting one of the most innovative flooring products on the market today.

Reach out to us! Twintec USA would be happy to share a more complete reference list or even organize a visit to one of our existing slabs. You can contact us at: info@twintecusa.com

If you are located outside of the USA, email our international business team at mail@twintecgroup.com or select one of our worldwide offices and contact them directly.

Topics: Concrete, SFRC, Jointless

Comments

If you liked this article please share it or add a comment below