Twintec Ultimate - Primark Phase 2 -Netherlands

Published on 30 September 2020

Finished Floor, Project Primark Roosendaal NL

Finished Floor, Project Primark Roosendaal NL

The investor LCP is a developer and asset manager who specialises

in logistics real-estate across Europe. Together with Dietz they

have extended Primark’s Distribution Center in Roosendaal (NL) to a

total floor area of 86,000m2.

The main contractor Sprangers Bouwbedrijf was responsible for the execution of this project. Due to their previous experience with Twintec Nederland, Twintec was again selected to design and

construct this new floor slab.

With less production costs and less CO2 emission (compared to a traditional floor slab) and a faster production time the seamless Twintec Ultimate floor was particularly suited for this job on piles. The high flatness tolerance specified of FM2 Special to TR34 3rd Edition (a Free Movement floor classification) was required due to the particular function of the warehouse and the high racking. Sprangers knew that Twintec could deliver this following their previous project together.

The floor has been produced by experienced workers using a Topp & Screed superflat screed and topping spreader achieving a very short production time of just 15 days (approximately 2,800m2 a day). The Twintec Ultimate floor slab design combines high performance steel fibres with steel mesh and a tried and tested concrete mix design that reduces the concrete shrinkage properties of the slab to deliver the seamless finish. The use of top mesh within the slab offers significantly improved crack control allowing a maximum crack opening within the floor slab to be guaranteed.

Advantages for the Investor and End-user

1. No opening joints or saw cut joint

2. Seamless/joint Free:

Reduced maintenance

Higher operational efficiencies

3. Reduced life costs:

Reduced ongoing maintenance to MHE equipment

4. Cost effectivenes:

This design solution can reduce the slab thickness, compared to traditional floor slabs.

Design, Build and Guarantee

How can we assist you?

Design: Despite this being an extension to an existing Twintec Ultimate floor slab, The Twintec

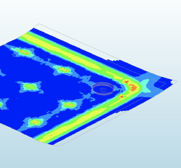

in-house engineering team reexamined all factors. With the DIANA program they simulated different loads, traffic, soil and floor slab to get the optimised floor slab on piles.

Build: The Primark project is a BREEAM certified project, achieving the level of BREAAM-NL Very

Build: The Primark project is a BREEAM certified project, achieving the level of BREAAM-NL Very

Good. By producing the Ultimate floor, Twintec has attributed to this certificate by using the hybrid

mesh, downsizing the production time and also by the machines which give less CO2 due to the filters used. In the construction process our experienced production team, using the laserscreed and topping spreader, obtained FM2 Special to TR34 3rd Edition. A very high standard and rarely used in the Netherlands.

Guarantee: The Twintec assurance guarantee is provided to all parties in a project. This incorporates insurances, warranties and advisory notes together with Twintec quality guarantees that result from employing professional staff throughout the business, a high level of customer service and a robust aftercare system.

Need more information, check the Blogs or contact our local office.

Topics: Twintec Ultimate, Warehouse, SFRC, Jointless

Comments

If you liked this article please share it or add a comment below