Price is what you pay, value is what you get

Published on 17 March 2023

Cold storage facilities are an excellent example where the interface management between subbase requirements, loads, choosing & placing the correct heating system, cold store wall panels, door openings and transition areas into ambient area, racking system (often as in this case, mobile racking), floor flatness requirements etc. need close attention to the engineering & construction detailing.

This is where the knowledge & experience of Twintec adds value not only for the end user but also for the investor, facility manager, general contractor and the local interdisciplinary building teams.

In emerging markets, this value cannot be underestimated.

CSK COLD STORE, TATU CITY, KENYA

CSK is developing a cold chain network of facilities across East Africa and the first cold storage facility is located in Tatu City, Nairobi, Kenya.

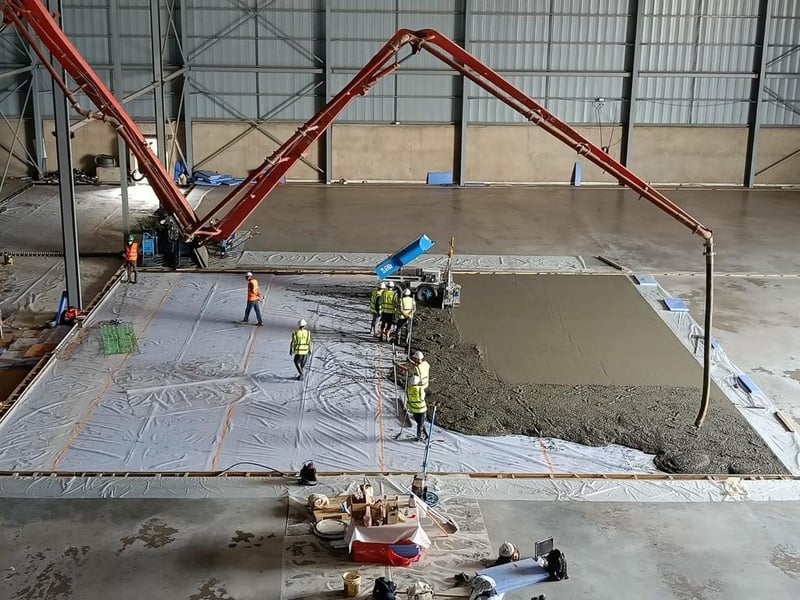

The cold store required a 14,000m2, superflat DM2 ‘jointless’ concrete floor slab, able to deal with temperatures ranging from 24 to minus 30 degrees and included the placing of rails inside the concrete floor slab for mobile racking.

Twintec provided their unique total offer concept solution [Design-Build-Guarantee].

DESIGN & ITS ALL ABOUT DETAILS

In the early planning stage of the facility, Twintec engineers were involved not only to design the concrete floor slab, but to work with the project team to optimise the cold storage building.

Coordinating the interface management & technical requirements between all disciplines was a critical success factor for the CSK facility from coordinating with the local engineer for the preliminary structural designs (substrate, sub-base and floor) and every step of the way to completion of the project. The integral involvement of building supervisors and contractors, being paramount for the final design solution. This resulted in 6 sub designs as Twintec tailor the static design per loading area.

The coordination of interface management (earthworks, floor heating, insulation wall panels etc… ) is key to make the designs work.

MATERIALS – THE RIGHT CHOICES

A key part of the preparation is to analyse the concrete batch plant, locally available materials, the quality of mixer trucks with detailed reporting on status and improvements to make. Nothing is left to chance with the concrete mix design tested with the local Kenyan materials at a laboratory in Europe, mix design trials and adjustments at site under Twintec supervision.

The site batch plant went through a full assessment 2 months before execution, adjustments made and closely monitored during execution.

Fibres, joints, and hardeners were selected based on a number of factors, it's about making the right choices technically, economically, and environmentally.

EQUIPMENT

Twintec commits to its sustainability values throughout every aspect of a project and used the Topp & Screed Electric Mini Screed for the first time in Africa.

The use of electrical equipment contributes to the reduction of CO2 and to the working environment of our workers. A key requirement for Twintec’s commitment to a sustainable future. The TS 6100e is equipped with a state-of-art laser system contributing to achievement of high tolerance requirements, easy to use and maintained by off-site remote centralised computer diagnosis.

EXECUTION - THERE IS NO SUBSTITUTE FOR EXPERIENCE

With all the concrete floor slab details implemented and controlled and the flatness requirements adapted to suit the MHE, racking type and lay out, all requirements are fixed in working and execution drawings.

Twintec’s international skilled execution team with a highly experienced on site Operations Manager ensured that the DM2 tolerance was achieved within the project time line.

The Twintec Difference

Twintec is uniquely placed to offer advice and to provide tailor made design solutions as a result of long term relations and experience worldwide with real estate investors, developers, consultancy firms, contractors, end users, local authorities, standards committees and universities.

There is an enormous amount of knowledge behind each project, this knowledge is where Twintec makes the difference to the rest of the market. This knowledge is needed to ensure quality and security AND this is the value each client gets……

For general international business enquiries, please contact the international business team via r.waugh@twintecgroup.com

Price is what you pay.. value is what you get.

Topics: Concrete, SFRC, design, cold stores, twintec, superflat, concretefloors

Comments

If you liked this article please share it or add a comment below