Industrial Concrete Floor Repairs and Floor Service

Floor Repairs and Floor Service for Industrial, Manufacturing, and Distribution Center Concrete Flooring

Concrete floors are generally durable and long-lasting. This type of flooring, however, can sustain damage over time. Moisture, for instance, can reduce the concrete’s compressive strength, making the floor less durable. On top of that, extensive traffic from facility workers, forklift trucks, and wheeled equipment can make your concrete floor dirty. This dirt could lead to hygiene problems, cause allergies, and damage onsite equipment.

Owners of industrial, manufacturing and distribution center floors are familiar with the challenge of maintenance and repair that goes into owning this type of floor. Whether your floor was made by Twintec Kalman or another company, the guide below will show common concrete floor repair and maintenance scenarios and procedures to get the most out of your industrial concrete floor.

Please note that Twintec Kalman warranty is longer and more comprehensive than any other offered by any industrial concrete floor contractor. The value of having our floor doesn’t end at providing durability and longevity. Our floors are green, too.

List of Common Floor Maintenance and Repair Scenarios

- Cracking

- Wear at Armored Construction Joint

- Typical Wear at Sawcut Joint or at Construction Joint

- Spall at Repaired Joint

- Spall at Sawcut or at Construction Joint

- Post-Tensioning Joint Repair

- Raveled Edge at Joint with Spalling and with Parallel Crack

- Spalled Edges at Old Walls, Removed Curbs, Plumbing Patches, Doorways, Conveyors, Infill, Etc.

- Spalls at Dock Door Channels and Other Metal Embeds

- Acid Attack at Battery Charger Floor

- Repair of Back-to-Back Armored Joint in a Shrinkage Compensated Concrete Slab with a Keyway as Load Transfer

- Old Rack Bolts and Old Guard Posts

- Broken Curb Face

- Potholes – Rock Pockets – Foreign Matter in Floor

- Pitting and Wear

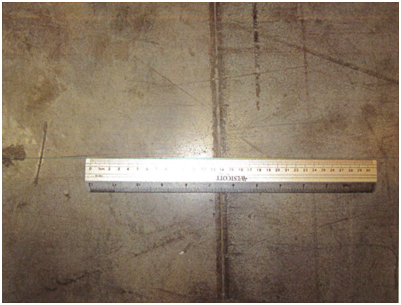

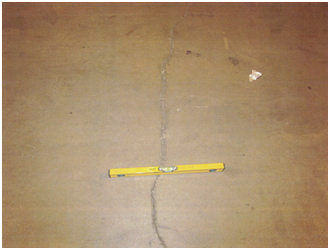

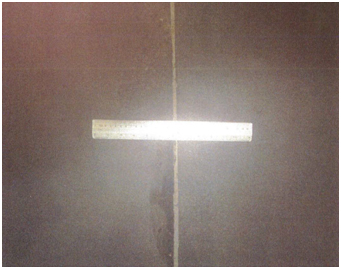

Cracking

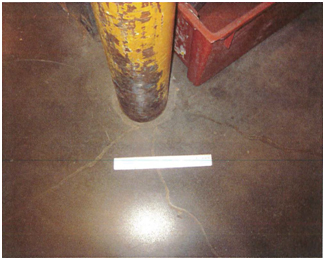

Some cracking is typical in all concrete floors. Most cracking is the result of slab restraint. In ambient conditions, slabs will expand and contract as the ambient temperature and relative humidity rises and falls. When concrete slabs cannot move freely because of embedded restraints or subgrade friction, they crack. Other floor slab cracking is typically caused by overloading the slab or failure of the sub grade to adequately support the slab.

For very narrow cracks 1/64″ or less, gravity filling may be insufficient because the injection epoxy will not penetrate enough with just gravity acting upon it. In these cases, one may not even want the crack filled. However, if desired, a pressure injection whether by bladder, hand or motorized pump of injection epoxy is needed. Such work is time consuming but very effective.

An example of a cracking near a guard post.

Typical slab restraints are objects like guard posts, welded angle frames at dock pits, equipment pads, and rebar ties to foundation walls and/or dock pits.

Cracking can occur when a slab is overloaded or the sub grade fails to adequately support the slab.

Wear at Armored Construction Joint

Wearing of the floor surface finish (spalling) on two sides of an Armored joint.

Wearing and cracking of the floor surface finish (spalling) on two sides of an Armored joint.

Forklift wheels can impact a joint and deepen the rut.

Shrinkage compensated concrete slabs where keyed joints were used instead of dowels for load transfer.

These photos show breaking of the floor surface finish (spalling) on two sides of a typical joint (armored and non-armored). Sawcut joints were made by the floor contractor when the floor was built. Construction joints were joints made by the floor contractor with forms (bulkheads), where the work was stopped for the day. Joint fillers are intended to act as a load transfer mechanism for wheels traveling across the joint.

Continued use of the floor in this condition will permit forklift wheels to impact the interface at the surrounding intact concrete finish, increasing the spalled area. Also, forklift wheels will impact the joint and deepen the rut as the wheel traverses it from both sides. Joint-free floor systems are a better buy because they do not have any joints except at the edge of each day’s work.

You can count on our team to fix the cracked or worn concrete construction joint in your commercial or industrial property at a cost you can afford.

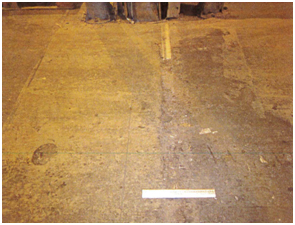

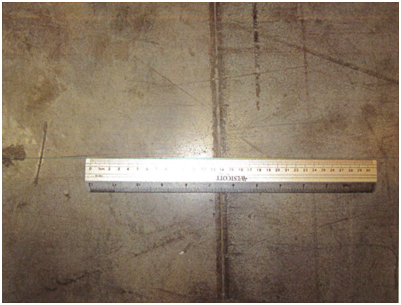

Typical Wear at Sawcut Joint or at Construction Joint

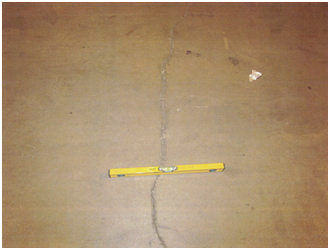

An example of a floor finish chipping and raveling at the interface of concrete and joint filler.

This photo shows a relatively intact floor joint (non-armored). The floor finish is chipped and raveling (spalling) at the interface of concrete and epoxy joint filler. Sawcut joints were made by the floor contractor when the floor was built, using a saw.

Construction joints were joints made by the floor contractor with forms (bulkheads), where the work was stopped for the day. Joint fillers are intended to act as a load transfer mechanism for wheels traveling across the joint.

Continued use of the floor in this condition will permit forklift wheels to impact the interface at the surrounding intact concrete finish, increasing the spalled area. Also, forklift wheels will impact the joint and develop a rut as the wheel traverses it from both sides. Since all concrete shrinks over time, all joints widen, and maintenance is required. Concrete shrinks mostly from the evaporation of water not needed to hydrate the cement. There is more shrinkage at slab surfaces than at their undersides, which is why concrete slabs curl upward at joints.

Need someone to repair a construction joint or sawcut joint? Twintec Kalman provides reliable and efficient concrete floor repair services.

Spall at Repaired Joint

Break-up of The Floor Surface Finish (spalling) on two sides of a repaired joint.

This photo shows break-up of the floor surface finish (spalling) on two sides of a joint that was repaired sometime in the past. Continued use of the floor in this condition will permit forklift wheels to impact the interface at the surrounding intact concrete finish, increasing the spalled area.

This repair held up well, except at the very edge of the joint. Perhaps this is due to slab curling. Slabs curl upward at their edges. No longer supported by the ground, they can flex beneath forklift traffic. When one edge is bent down under load, the adjacent edge is easily impacted. It gets chipped (spalls) and erodes with continued use.

Remediating a spall at a repaired joint can take a lot of time and effort. Instead of taking care of the problem yourself, let our concrete floor repair team get the job done correctly and efficiently.

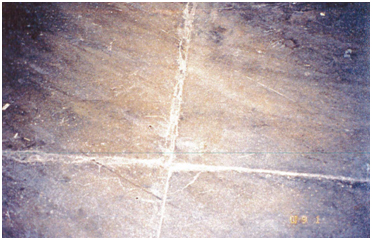

Spall at Sawcut or at Construction Joint

An example of Spalling on two sides of a typical joint.

This photo shows break-up of the floor surface finish (spalling) on two sides of a typical joint. Sawcut joints are those made by the floor contractor when the floor was built.

Construction joints are joints made by the floor contractor with forms (bulkheads), where the work was stopped for the day. Joint fillers are intended to act as a load transfer mechanism for wheels traveling across the joint.

Continued use of the floor in this condition will permit forklift wheels to impact the interface at the surrounding intact concrete finish, increasing the spalled area. Also, forklift wheels will impact the joint and deepen the rut as the wheel traverses it from both sides. This condition is why joint-free floor systems are a better buy, since they do not have any joints except at the edge of each day’s work.

The fix for spalling may vary depending on factors, such as the type of concrete found in your facility and the extent of the problem. Rather than repair the problem yourself, let our team do it for you.

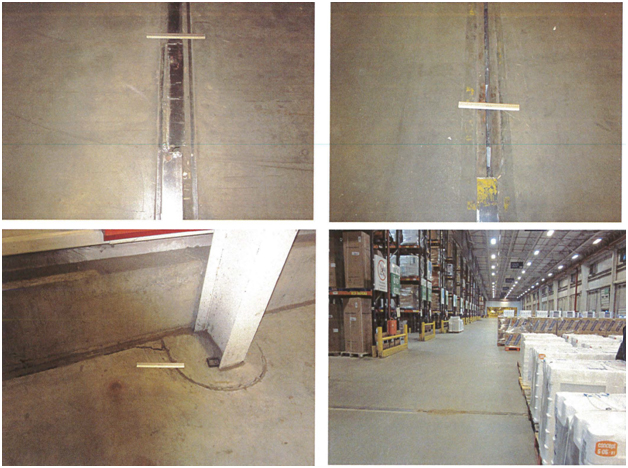

Post-Tensioning Joint Repair

e

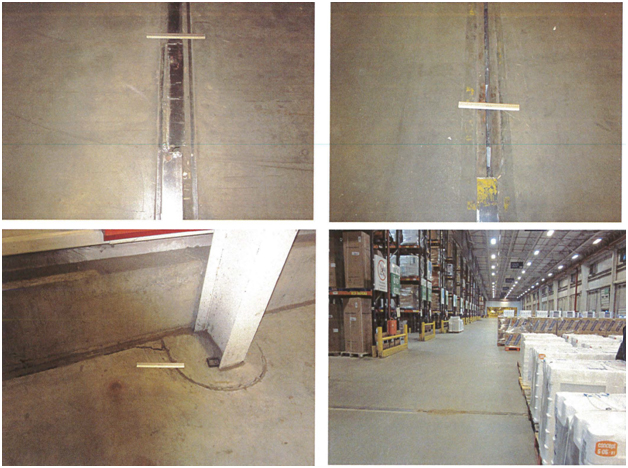

Four examples of post tensioned slab joints.

Post-tensioned armored construction joints have been identified by Kalman as, potentially, the most difficult repair. The joint assembly consists of embedded steel angles on each side of the floor joint, inverted to hold a cover plate. The plate is welded by design to the embedded angle on one side of the floor joint only and is designed to bridge the joint opening as traffic crosses the joint (see photos). The joint moves thermally in the dry storage/non-food areas with the seasonal temperature changes (evidenced by the movement and crack at the column – pictured above). In the summer the slabs are warmer and expand. In the winter, the slabs are cooler and contract. All of the slab movement necessarily takes place at the armored construction joints. The joint opening beneath the plate during the May 2016 inspection was approximately 1″ wide.

The angle with top cover plate design is more suitable for pneumatic tires than for warehouse floors. Hard wheels impacting the plate and angle assembly wear the wheels so they need to be replaced more frequently. Repeated impact from the hard wheels on the plate break the plate loose. Some places within the facility have lost the plate and have had to re-route fork lift traffic.

Before any remediation work, Twintec Kalman strongly recommends a thorough investigation of the as-built location and details used for the post-tensioned construction (anchor types location, etc.). Non-grouted post tensioned strands should be carefully avoided because they are in tension and, without grout, they are not restrained if severed.

When remediation is required after the investigation, reach out to us as soon as possible. Our skilled industrial concrete floor repair team will take care of the spall at the construction or sawcut joint.

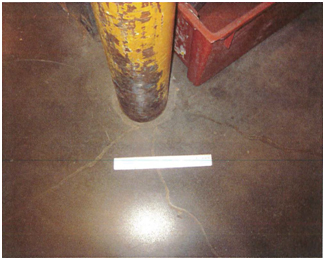

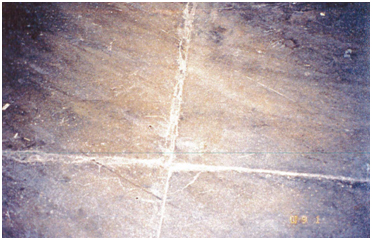

Ravelled Edge at Joint with Spalling and with Parallel Crack

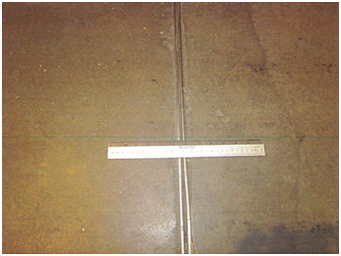

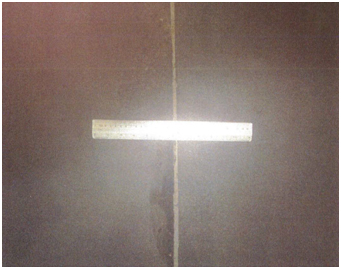

Examples of parallel cracking and a raveled edge at the joint.

This picture shows cracking parallel to the floor joint on the left side of the photo’s foreground. In addition, the joint is raveling (spalling). The joint filler is missing in portions of this joint. Let our industrial concrete floor repair company fix any raveled edges in the concrete joints of your facility. Our experienced team will get the work done efficiently and with minimal disruption to your business operations.

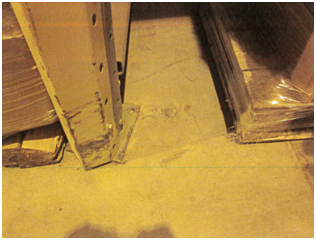

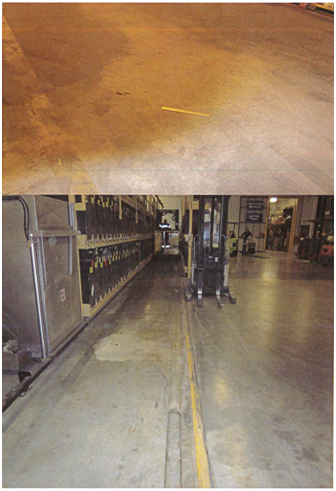

Spalled Edges at Old Walls, Removed Curbs, Plumbing Patches, Doorways, Conveyors, Infill, Etc.

An example of outer broken slab edges in need of repair.

An example of a central strip of concrete that needs to be resurfaced.

The outer broken slab edges need to be repaired in the same fashion described for spalled joints. In addition, the central strip of concrete shown should be resurfaced. Resurface with epoxy mortar or fast setting modified concrete mortar, time permitting.

If crossing this joint is more rough than desired, it may be resurfaced between the steel rails, or the rails taken out and the slab removed to the sub-grade and fully replaced. In that instance, the new concrete is to be tied with rebar dowels epoxied into one (not both) slab face spaced at 9″ c/c top and bottom, staggered 4-1/2″ from top to bottom.

An example of a partial repair that needs to be resurfaced.

The slab between the steel in the above photo has been partially repaired. The repair is holding up, but the finish is damaged enough to warrant resurfacing with fast-setting modified concrete mortar or with epoxy mortar as time permits.

Whether the spalled edge is at a doorway, infill, removed curb, old wall, or other locations, you can rely on our team to remediate that problem.

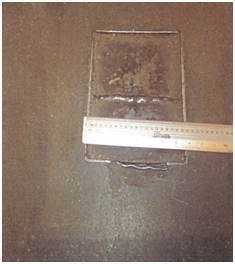

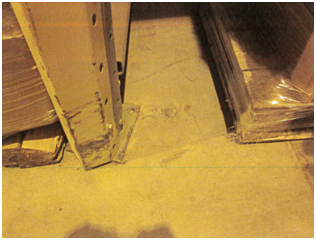

Spalls at Dock Door Channels and Other Metal Embeds

Examples of spalling at dock door channels and other metal embeds.

This photo shows a steel angle embedded at of the dock pit doorway. The concrete edge at the angle has a 3″ x 16″ hole adjacent to it. Left untreated, the spalling will increase further back from the angle and along into the Dock. Additionally, the floor will eventually begin to rut immediately along the concrete/angle interface.

More substantial repair would include the complete removal of the plates to the rightmost angle. If the concrete beneath is sound and joint-free, it can be resurfaced, otherwise completely removed and replaced.

Whether the solution requires resurfacing or complete removal and replacement of the plates, you may count on our professional concrete floor repair company to fix the spalling in your industrial or commercial facility.

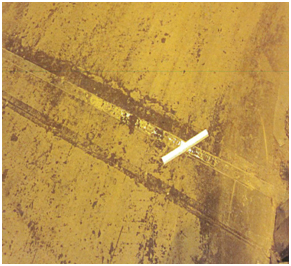

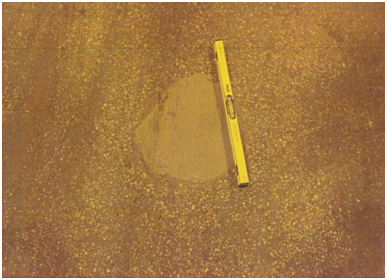

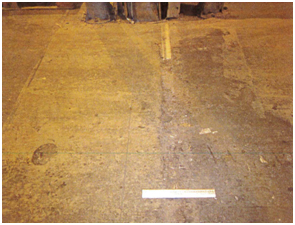

Acid Attack at Battery Charger Floor

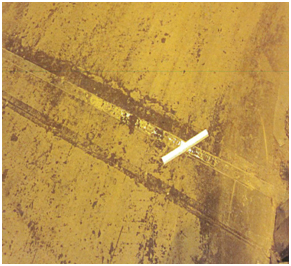

In these two photos, battery acid spills have damaged and weakened the floor finish.

The floor finish along the battery charging stations in this photograph is gone. Acid attack from battery acid spilling over and onto the floor has weakened the finish and, along with traffic, disintegrated the finish. Depth of finish loss is typically 1/16″ to 1/8″ but can be as much as 1/2″ or more. Acid stains on the surface in the battery charging area are present and have discolored, but not significantly damaged the floor. Scrubbing the floor to remove acid residue on a regular basis with baking soda and water is recommended.

Our concrete floor repair services also include fixing concrete floor finishes that have been weakened or destroyed by acid. We have repair specialists who use state-of-the-art equipment and high-quality materials to restore your floors and make them look brand new again.

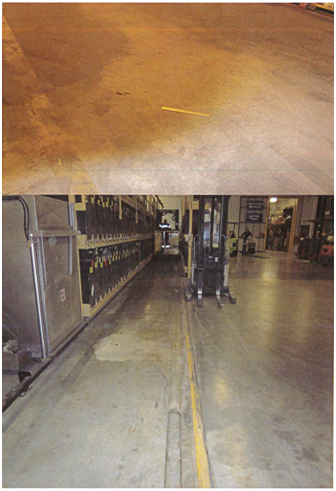

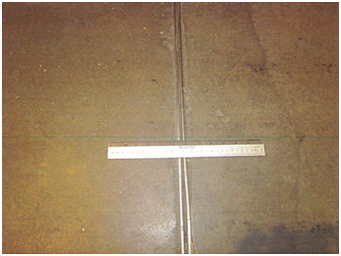

Repair of Back-to-Back Armored Joint in a Shrinkage Compensated Concrete Slab with a Keyway as Load Transfer

In these two photos, a keyway and surface grinding have created the need for repairs to this concrete floor

Keyways should not be used in industrial warehouse construction for load transfer. Most keyways are tapered so that one side of the floor joint can move down relative to the other side of the floor joint with forklift traffic. This is the case in many locations in the facility where keyways were used.

For additional load transfer design details and recommendations, please refer to the latest edition of ACI 360 -Design of Floor Slabs on Ground.

Additionally, in the main speed aisle, some surface grinding was done to lower the concrete surface but left the armored joints high. The combination of the keyway and the surface grinding have created a bump at the joint.

We recommend turning to us for warehouse concrete floor repair if a keyway and surface grinding has damaged your flooring. Our team will fix the problem without causing significant disruption in your everyday industrial operations.

Old Rack Bolts and Old Guard Posts

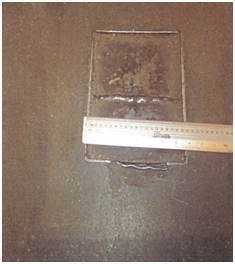

Above: Photo of the remainder of bolts from a rack system.

The concrete spall around the bolt remnants is likely from the original bolt installation or from the rack removal process and forklift traffic.

Above: Photo of the remnant of a guard post.

The remnant of a guard post was cut nearly to finished floor elevation. The interior post fill concrete is rough and the floor concrete around the post is chipped (spalled).

Our concrete floor repair services fix concrete spalls caused by an old guard post or an old rack bolt. We get the job done as efficiently as possible without causing major downtime or disruptions to your warehouse business.

Broken Curb Face

An example of a damaged curb face.

The bottom of the face of the curb is missing. Impact from pallets and forklifts have broken away the concrete cover to a depth of approx. l” or more into the curb.

Left as is, this condition contributes to an unsightly, unsanitary facility. The amount of impact is extraordinary, both in number of impacts as well as apparent force of impact evidenced by the depth of penetration.

Though the curb still functions to protect the wall, it should have the face rebuilt to prevent further disintegration and provide a more sanitary condition at the curb/floor intersection.

Let our industrial concrete floor repair team fix this damaged curb face. We’ll use the latest tools and equipment to restore the face of the concrete curb efficiently and effectively.

Potholes – Rock Pockets – Foreign Matter in Floor

Above: Photo of a repaired “hole” in the floor.

The hole in the floor was filled with an epoxy to permit traffic to operate unimpeded. In this particular photo, the “hole” is more likely a guard post remnant – but this photo was used to provide an appearance example.

Holes in the floor are typically the result of foreign matter – wood chips – mud balls – or other items that arrived in the freshly mixed concrete.

When finishing a floor these items are undetectable and a thin layer of finished floor covers them. Forklift traffic breaks the thin layer and reveals the objects, which often loosen and come out of the floor.

Rocks that rolled under troweling form rock pockets, which are hollowed areas with rocks residing in them. Often the top of the hollowed area enlarges to the point where the rock can be bounced out or picked out of the floor.

Sometimes, holes in the floor are the result of impact to the floor during construction or shortly after construction. Rack installation is a frequent source of gouges.

As your concrete floor repair company, we restore the flooring in your industrial facility or commercial establishment by fixing these holes. You may rely on our team of concrete specialists to make your floor look as good as new.

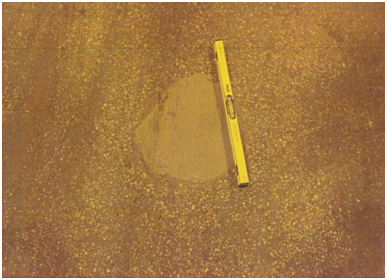

Pitting and Wear

An example of the worn finish on a concrete floor.

Industrial floor finishes are constructed to be dense and very abrasion resistant, thus resistant to pitting. Pitting is the formation of widespread, very small holes close to each other and the floor finish has the appearance of coarse sand paper.

Pitting is the wearing out of the finish, though less likely due to sliding friction and more likely the consequence of residue or items on the floor crushing under traffic.

Premature finish wear can be the result of poor finish quality. If the slab contractor did not deliver a dense durable finish it may wear unfavorably compared with similar floors. Sometimes concrete carbonation, the reaction between wet concrete and carbon dioxide to form a chalky soft finish, is the culprit. Acids, in any form, but especially low concentrations permitted to remain in place or repeatedly wet and dry can weaken good quality concrete.

Housekeeping is an important role in maintaining the service life of a concrete finish. Overly aggressive cleansers can weaken cement paste. When cleaning the floor, the residue needs to be retrieved from the finish. Floor scrubbers are often operated so quickly that the floor is simply wet and scrubbed, with the residue remaining behind on the floor, instead of collected in the on-board tank of the scrubber. Dirty floors can lead to pitted floors.

To contact us about any of the above information, feel free to contact us on:

jointfree@twintecusa.com or call us on:

+1 704 896 5955.